About The Department

KCG College of Technology was awarded an award titled as “”The Emerging College for Fashion Technology Studies” during the Namma Chennai Fashion and Business Awards 2020-2021″, held on 26th February 2021.

School of Fashion Technology, KCG College of Technology has been awarded as the “Outstanding Fashion Institute with Best Infrastructure” in the 22nd World Education Summit & Awards held on 17-18th December 2021.

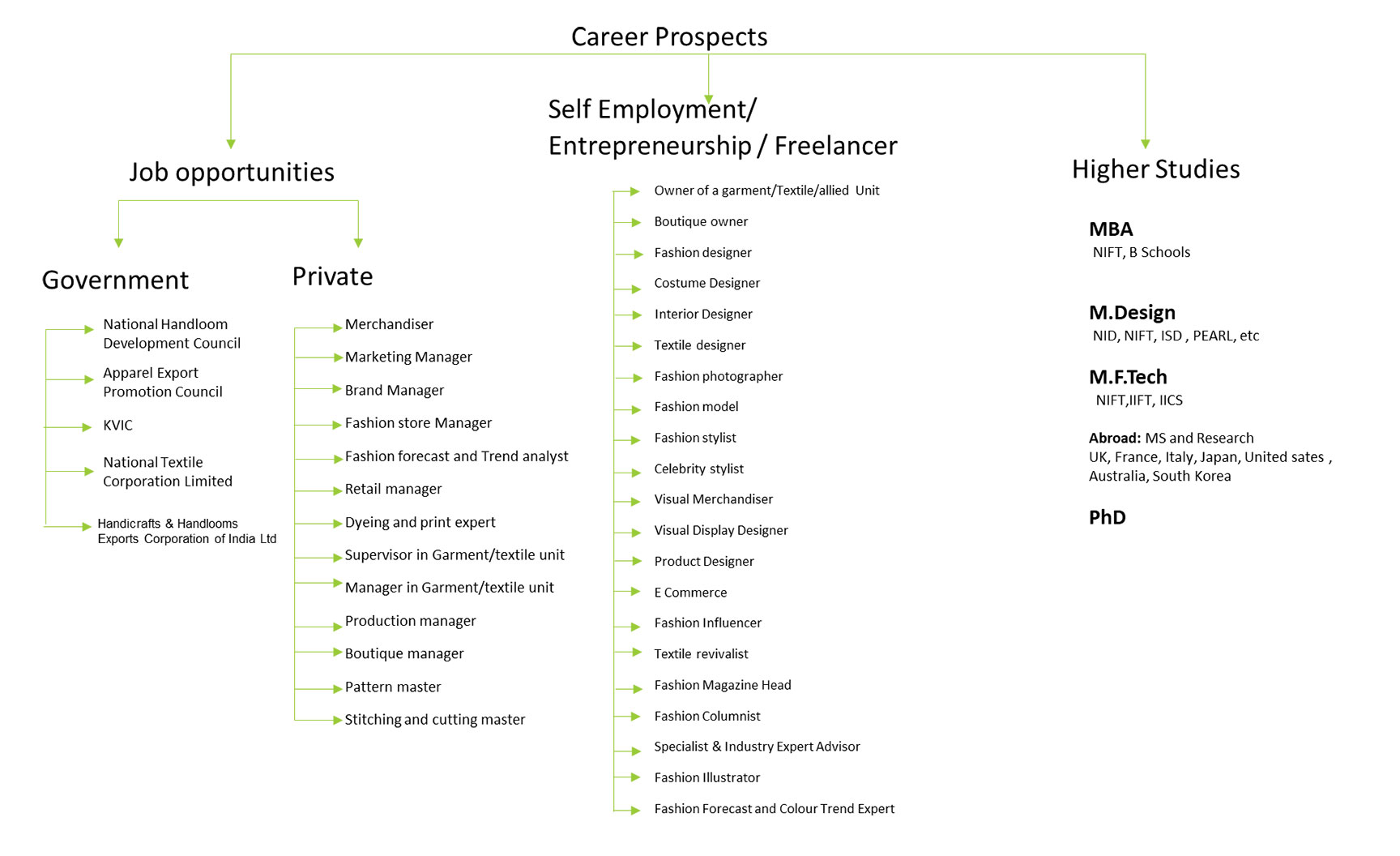

KCG College of Technology has 4 years B. Tech. Fashion Technology program, which aims to inculcate technical expertise and a creative edge amongst the students who aspire to become fashion technocrats. The students will be trained to produce innovative, aesthetic and functional fashion products paving way to establish sustainable fashion business.

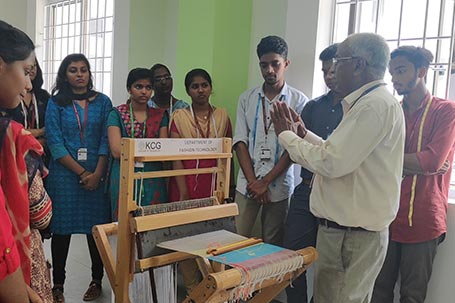

The Department aims to provide hands on experience on the best practices followed in the global apparel industry. Apart from classroom lectures, the students will be given opportunities to interact with industry experts through lectures, seminars, analytical and problem solving exercises, case studies, courses offered by industry, intensive internships, and real time research projects,. This value added education of the institute drives the students to professionally survive in the international apparel arena too.

Department Video

Vision

The Department of Fashion Technology aims to be a centre of excellence to create fashion technocrats by inculcating creativity, technical expertise and managerial proficiency for contributing innovative, aesthetic and functional fashion clothing to the society.

Mission

- Impart comprehensive technical knowledge with ethical values in all fashion apparel domains to contribute sustainable fashion products to the society.

- Imbibe professional approach and hands-on-experience through state-of–the-art infrastructure.

- Inculcate creativity and analytical thinking to provide techno-economic solutions for the advancement of apparel industry.

- Instill life-long learning to build excellent careers in higher education, employment, research and entrepreneurship.

Programme Educational Objectives

Bachelor of Fashion Technology curriculum is designed to prepare the graduates having attitude and knowledge to

| PEO1 | Have powerful base to pursue a successful professional and technical career. |

| PEO2 | Have strong foundation in basic sciences, mathematics, engineering and experimentation skills to comprehend the manufacturing processes and provide practical and innovative solutions. |

| PEO3 | Have knowledge on the theory and practices in the field of fashion technology and allied areas to manage apparel industry and provide techno-economic solutions to the problems. |

| PEO4 | Engross in life-long learning to keep abreast with emerging technology. |

| PEO5 | Practice and inspire high ethical values and maintain high technical standards. |

Program Outcomes

| PO 1: | 1.Engineering Knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems. |

| PO 2: | 2.Problem Analysis: Identify, formulate, research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences. |

| PO 3: | 3.Design / Development of Solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations. |

| PO 4: | 4.Conduct Investigations of Complex Problems: Use research based knowledge and methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions |

| PO 5: | 5.Modern Tool Usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modelling to complex engineering activities with an understanding of the limitations |

| PO 6: | 6.The Engineer and Society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice. |

| PO 7: | 7.Environment and Sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of and need for sustainable development. |

| PO 8: | 8.Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice. |

| PO 9: | 9.Individual and Team Work: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings. |

| PO 10: | 10.Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions. |

| PO 11: | 11.Project Management and Finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments. |

| PO 12: | 12.Lifelong Learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change. |

Programme Specific Outcomes (PSOs)

The graduates of Bachelor of Fashion Technology will be able to:

| PSO-1 | Analyze, design and solve complex problems in textile based garment and fashion industries |

| PSO-2 | Apply fundamental and technical knowledge and skill to become a successful entrepreneur and execute fashion business in the areas of garment design, development and manufacture |

| PSO-3 | Develop ethical products and manufacturing processes in the fashion and garment fields as per societal requirements. |

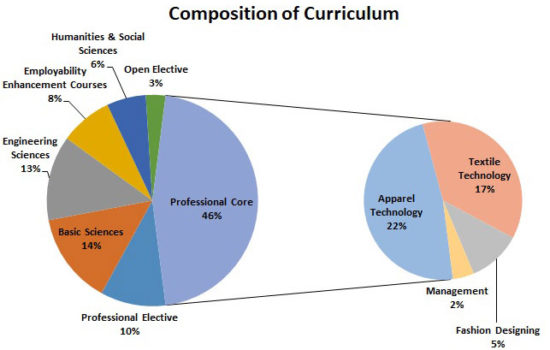

| UG (Under Graduate) | |||

| B.Tech. – Fashion Technology – 4 Years (Started in 2018) | Regulation 2017 | Curriculum & Syllabus | Course Mapping |

| Regulation 2021 | Curriculum & Syllabus | Specialization |

Textile Technology

Basics of Textile Technology

Technology of Spinning Processes

Characteristics of Textile Fibres

Textile Chemical Processing

Fabric Manufacturing

Knit Fabric Production

Textile Quality Evaluation

Woven Fabric Structures

Fabric Analysis Laboratory

Textile Chemical processing Laboratory

Textile Quality Evaluation Laboratory

Fashion Designing

Concepts of Fashion and Design

Fashion Evolution

Fashion Illustration Laboratory

Fashion Design Laboratory

Apparel Technology

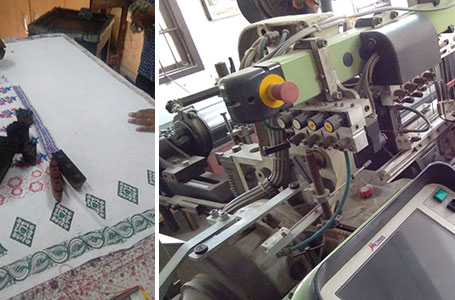

Fundamentals of Garment Manufacturing

Pattern Engineering

Garment Production Machinery

Garment Construction

Industrial Engineering in Apparel Industry

Apparel Production Planning and Process Control

Apparel Costing

Garment Finishing and Clothing Care

Garment Accessories and Embellishments

Pattern Engineering Laboratory

Garment Construction Laboratory

Garment Machinery Laboratory

Computer Aided Garment Design

Laboratory

Management

Apparel Marketing and Merchandising

Professional Elective

Computer Application in Apparel Industry

Knit Wear Development

Denim Manufacturing

Protective Garments

Apparel Size and Fit analysis

Intimate Apparel

Clothing Comfort

Production and Application of Sewing Threads

Home Textiles

Fashion Photography

Fashion Portfolio Development

Application of ERP and MIS in Apparel Industry

Disaster Management

Quality Assurance in Fabric and Garment Production

Fashion Management

Fashion Management

Operations Research in Textile Industry

Intellectual Property Rights

Professional Ethics in Engineering

Retail Management and Visual Merchandising

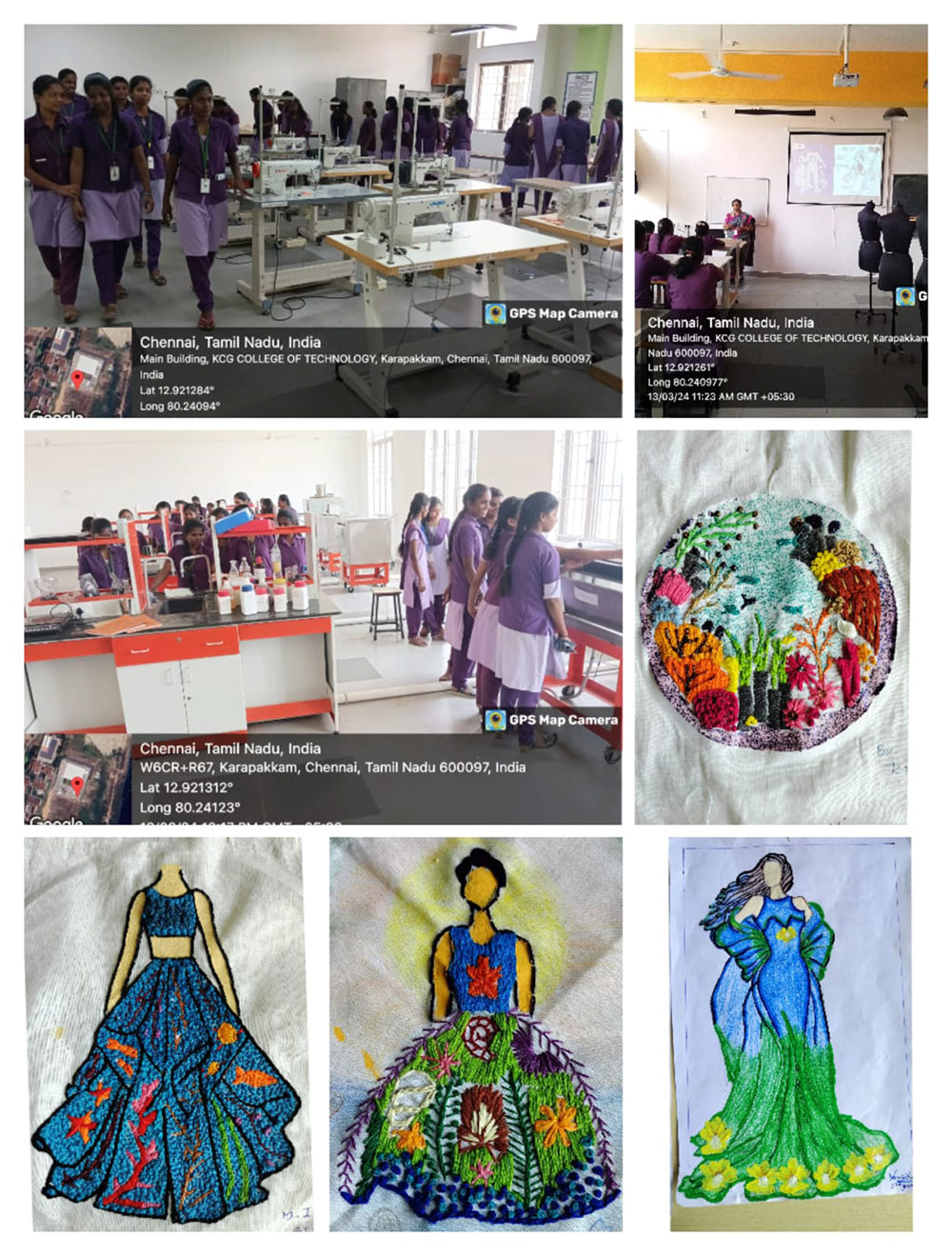

Charles Frederick Worth Fashion Designing laboratory

Ebenezer Butterick Pattern Making Laboratory

Elias Howe Garment Construction Laboratory

Joseph Marie Jacquard Fabric Analysis and Textile Quality Evaluation Laboratory:

John Mercer Textile Chemical Processing Laboratory:

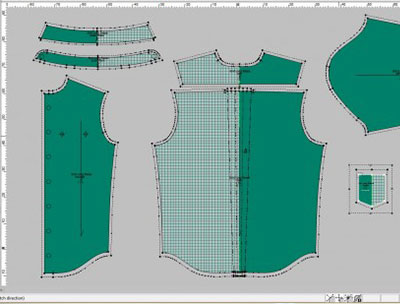

Levi Strauss Computer Aided Garment Designing Laboratory:

- This lab facilitates the students to improve their skills in using the modern tools for designing garments, woven, knitted and embroidered fabrics & pattern making, grading and marker planning.

- This lab has computers, digitizer, plotter, scanner and software for fabric designing, fashion designing, and garment designing.

- This lab will help the students to develop the soft skills required in developing E-prototypes with the speed and quality expected by today’s fast fashion industry.

- The skills acquired in this lab gives a great amount of confidence to the students as they can get multiple diversities and can sought careers in various coveted fashion fields.

|

|

| Bharath Tex 2024 , conducted the Hackathon under the National Technical Textiles Mission 26th to 29th Feb 2024, Miss. Subha K. and Miss. Samyuktha S. of 3rd year participated and won the winning award, they haven beem recommended for funding of up to Rs. 50 Lakhs under the GREAT funding scheme. Project idea: JUTE – BANANA – COTTON FIBRE REINFORCED NON-WOVEN COMPOSITES THERMAL INSULATOR” under the guidelines of Dr. G. Mohamed Zakriya. | |

|

|

| Mr. Surya Bharath, 2018-22 batch secured the Anna University 3rd Rank with 8.77 CGPA. | Texathon 2.0 Conducted by startup TN Textile Hackathon in collaboration with the Atal Incubation Centre (AIC), NIFTTEA Incubation Center for textile and apparels, Tiruppur, students (Nausheen, Neha Mergu) were awarded and won a cash amount of Rs 10000 for their project presentation on the tilite of “Electromagnetic Radiation protective and Smart Textile” |

|

|

|

|

| Surya Bharath,4th year won First Prize in a multi-disciplinary project conducted by Pragati 2022, National level Business Plan Competition and Exhibition. | Nausheen AL ,2nd year won First Prize in a Fashion Illustration contest conducted by Texvalley,Erode |

|

|

| Surya Bharath of 4th year won Best project Idea Bachelor’s category ,IMP 2021 by IIT Hyderabad | |

|

|

| Surya Bharath,4th year won First Prize in a multi-disciplinary project conducted by Pragati 2022, National level Business Plan Competition and Exhibition. | Nausheen AL ,2nd year won First Prize in a Fashion Illustration contest conducted by Texvalley,Erode |

|

|

| Dr. G. Mohamed Zakriya, Faculty of SoFT was awarded National Societal Innovation Award of the year 2019 | Surya Bharath,4th year won First Prize in a multi-disciplinary project conducted by IUCEE foundation. |

|

|

| Surya Bharath of 3rd year, has been awarded as Runner Up and a cash prize of Rs.50,000 at KCG PITCH FEST LIFT OFF 2021 |

Surya Bharath of 3rd year, has been awarded First Prize in the YOUTHZEST 2021 |

|

|

| Surya Bharath of 3rd year, has been awarded First prize in the IUCEE NEP Student Competition 2021 |

T.Swetha, L.Prathiksha and C.Jeevitha of 2nd year were the winners of KCG Ideathon 2021 , Theme: Green Technology |

|

|

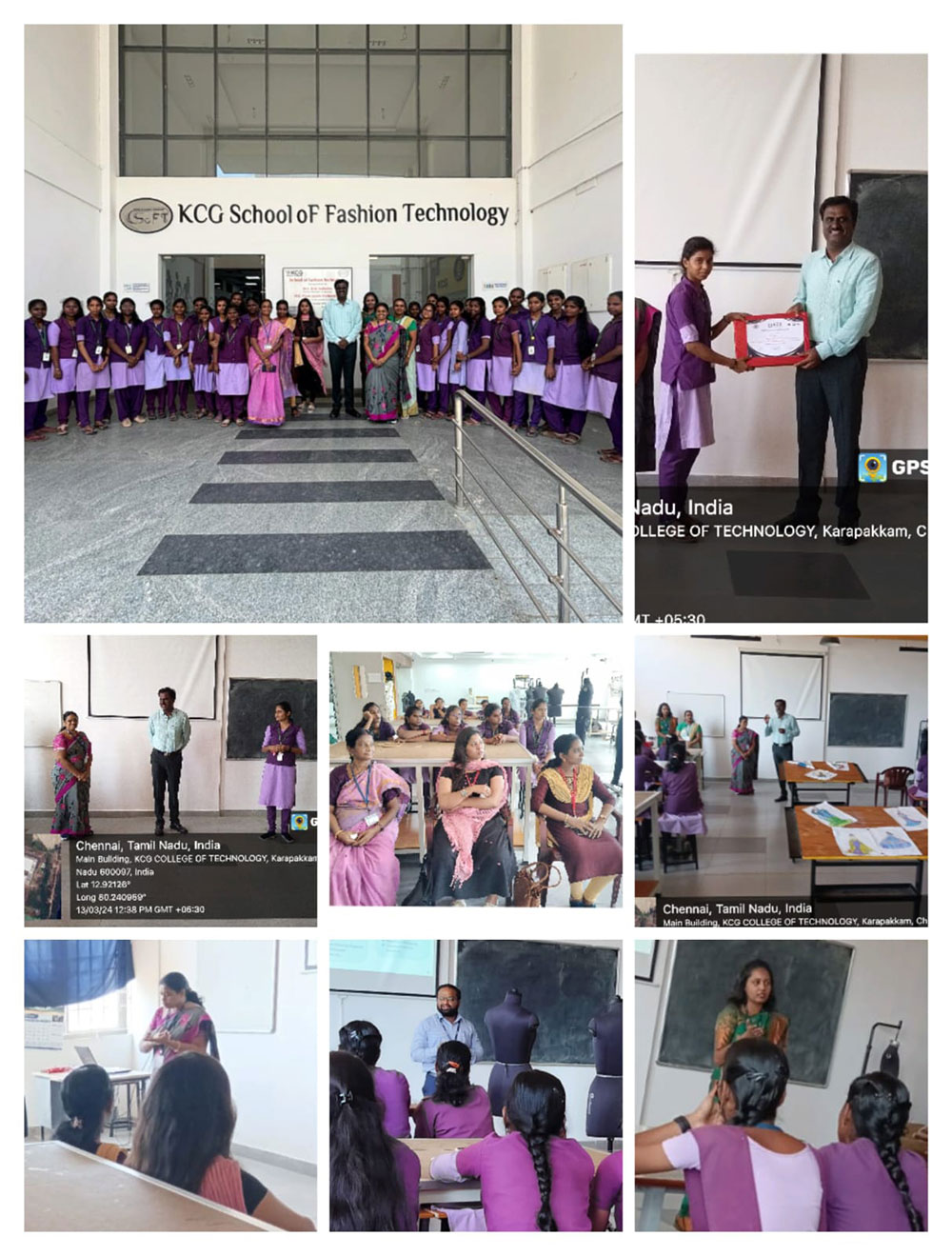

| “Career prospects in the fashion industry” an awareness session organised for the final year students of Dharmambal polytechnic, Taramani on 13/3/24. Competitions were conducted for the students and prizes were given to the students. | |

|

|

| Industrial Engineering | Textile Printing |

|

|

| Grooming | Fashion Portfolio |

|

|

| Students of SoFT organised the event Threads and trends for school students in Engenius 2024 | Training Program |

|

|

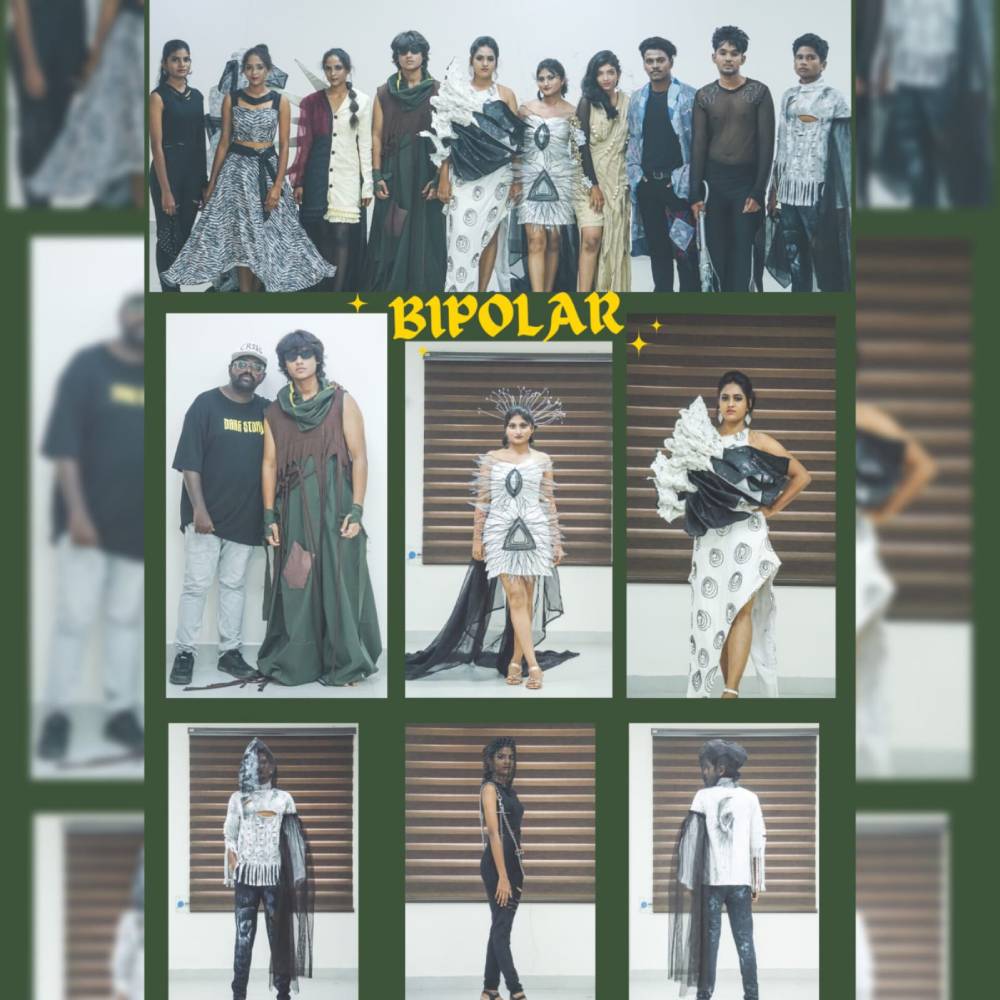

| 3rd and final year students participated in the Avant- Garde fashion India Fashion show conducted by Ramp Culture, at NIFT Chennai campus on 30-09-2023. 20 designers presented their collections on 2 themes namely bipolar diversities and handloom- the heritage rulers. | |

|

|

|

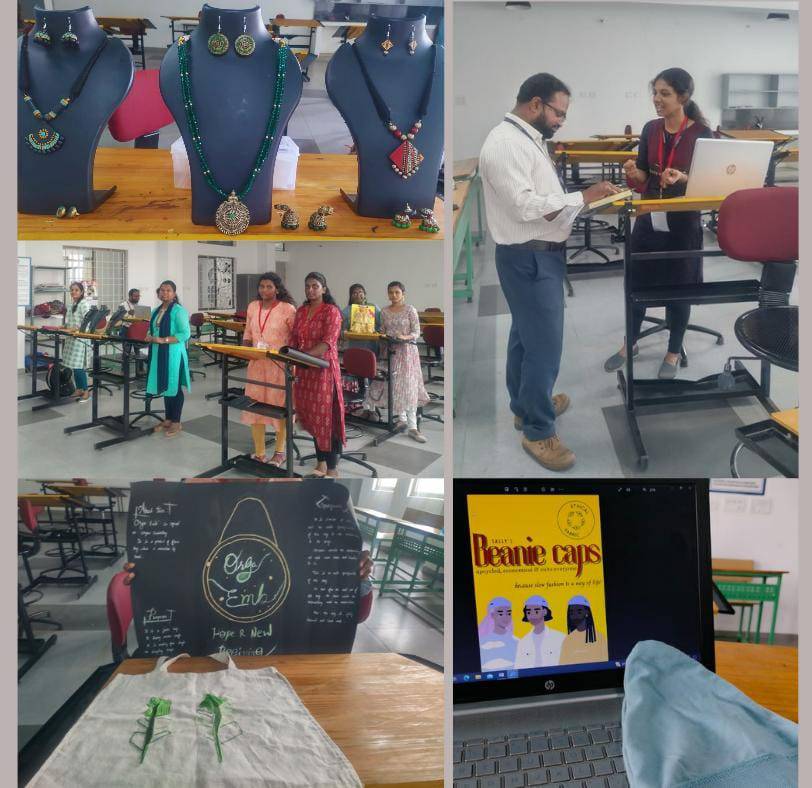

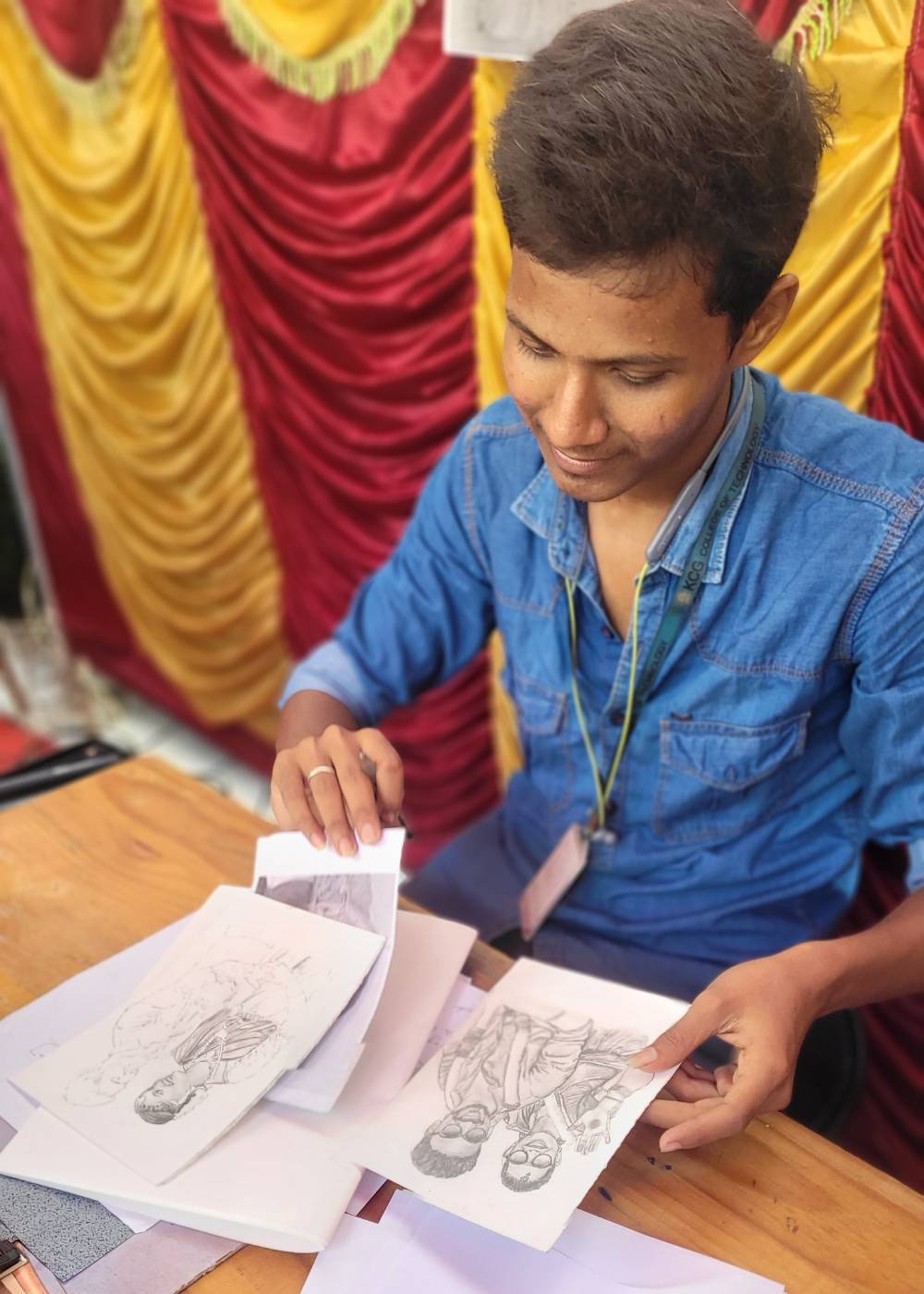

| Vivanta National Level Inter-college technical symposium was conducted. 3rd and final years were involved in coordinating the various events and activities like Paper presentation, 3D fashion illustration, Product presentation are the events organized by Fashion Technology. The Segai team also organized a stall which sold customized artefacts done by SoFT students. | ||

|

|

|

| 3rd and final year students presented their collections in Ethereal – the inter collegiate cultura event at KCG on 13th Oct. 23. 23 designers presented their collections on 3 themes namely convertible garments, bipolar diversities and handloom- the heritage rulers. | ||

|

|

|

|

| Handloom day was celebrated with the 2 contests, 2 seminars, 1 lucky dip contest and a handloom exhibition for 5 days. | |

|

|

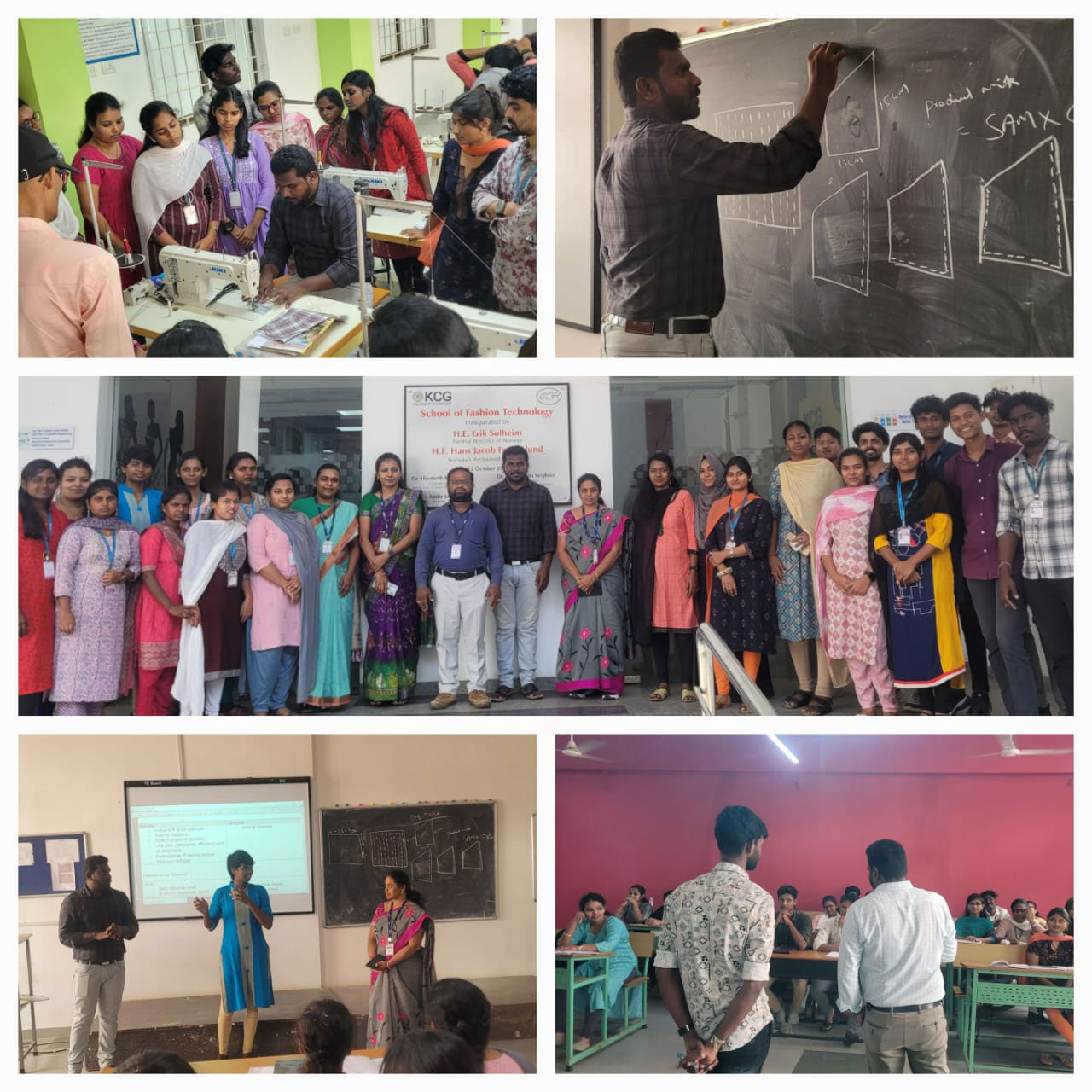

| Industrial Engineering Techniques & Application in Garment Industry – Mr Sreedhar Gunasekaran | Merchandising practices in Garment Industries – Mr. Somasundaram |

|

|

| International Fashion Brands – Proactive Employability Skills for a Successful Career in International Retail Brands – Mr. T. Vimal | M/s. Magnum Clothing Pvt. Ltd (Industrial Visit) |

|

|

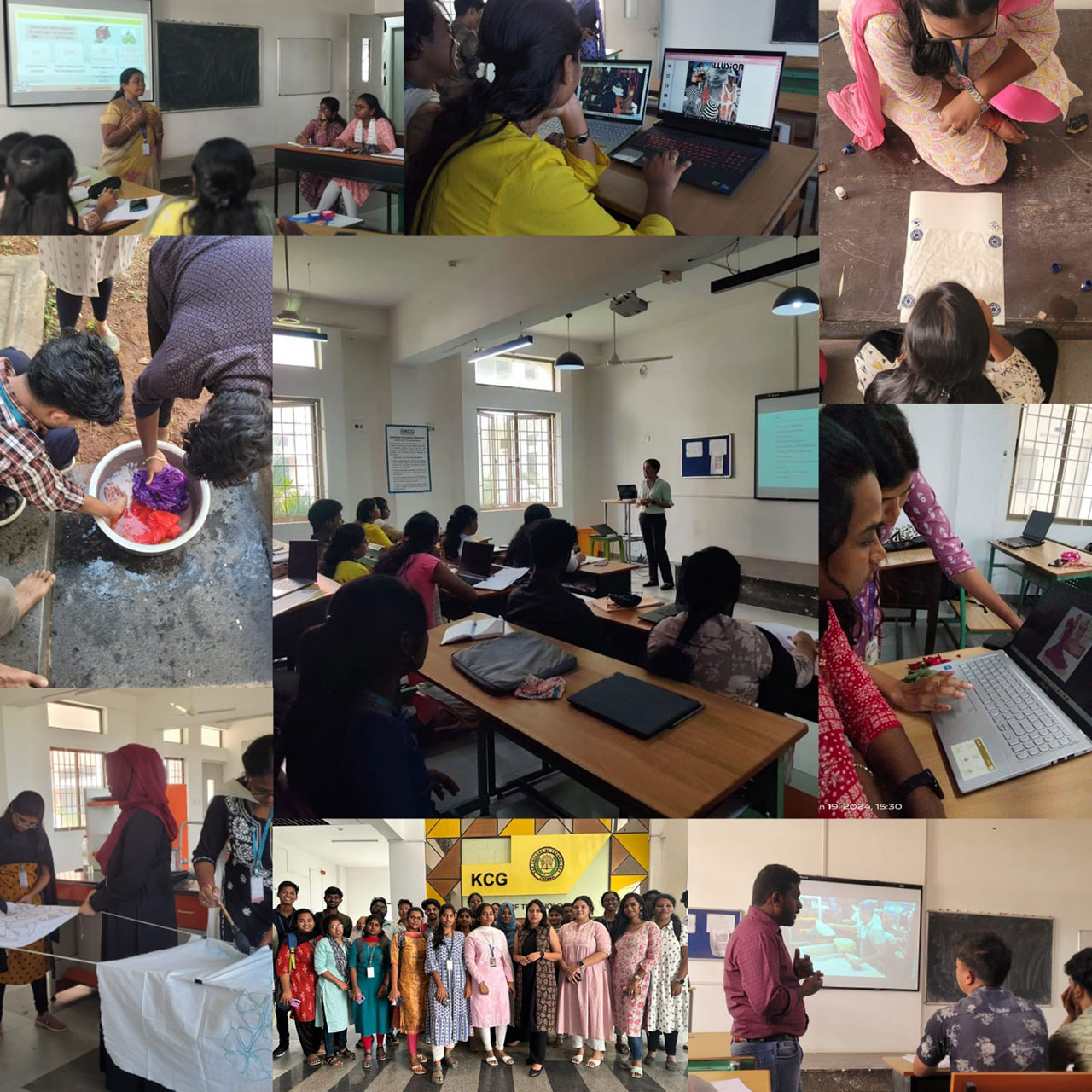

| International conference on AI in fashion and design, Bangalore | Skill Development Training Program-2022 |

|

|

| Poster presentation | COLOURICIOUS 2022-Inter school Embroidery contest |

|

|

| SoFT Department Inauguration | |

|

|

| Industrial Visit to Weavers’ Service Centre (WSC), Chennai | |

|

|

| Guest lecture by Ms.Aishwarya Raghunath,A celebrity fashion and costume designer | |

|

|

| Tie and Dye Workshop (06.03.2021) | |

|

|

| SEI GAI Brand Launch | Virtual Fashion show |

|

|

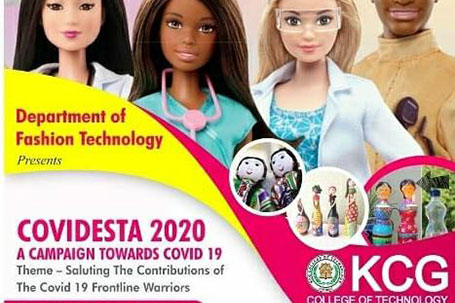

| COVIDESTA Campaign | Fashionista-National level school fest for school students |

|

|

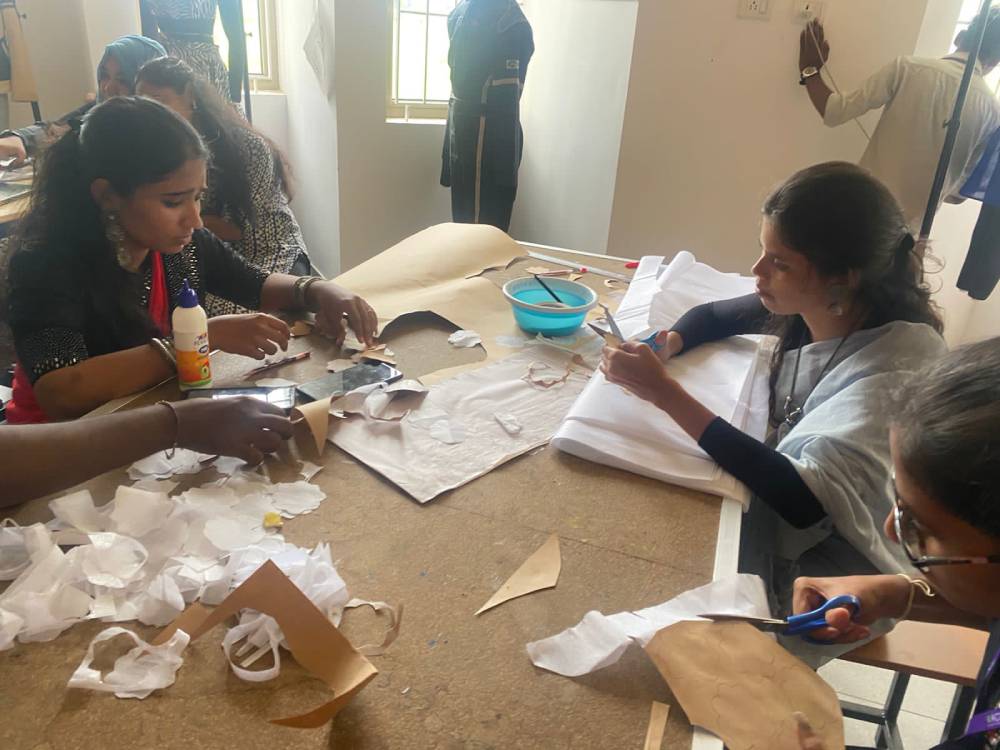

| pattern making workshop | Tie & Dye workshop |

|

|

| Madras Coture Fashion | 3D Printing |

|

|

| Conceptualization Creation and Application of Textile Design | Texvalley Weave Event |

Student start ups

Students of the second years Ms.Girija.V and Ms. Rithisha.R have won the runner up position and won Rs.2500 in NIFT Spectrum (Chennai) for the event face painting, the theme of that event is puzzle of time-Past, Present, Future.

K. Subha and S. Samyuktha of III B. Tech FT won the best paper presentation award in the Track 3 – Haute Tech, paper presentation contest conducted by VIT Chennai in their Techno VIT- technical symposium on 6th Oct 2023

Surya Bharath,4th year along with the team incubated PALFTEC R&D PVT LTD start up in the college

School of Fashion Technology signed an MoU with M/s. Thanuja’s Exim, Chennai .Thanuja’s Exim has offered a consultancy on the topic.

Creative corner

Video Gallery

Prepared greeting cards for the Teacher’s day

Organized a stall which sold customized artefacts done by SoFT students

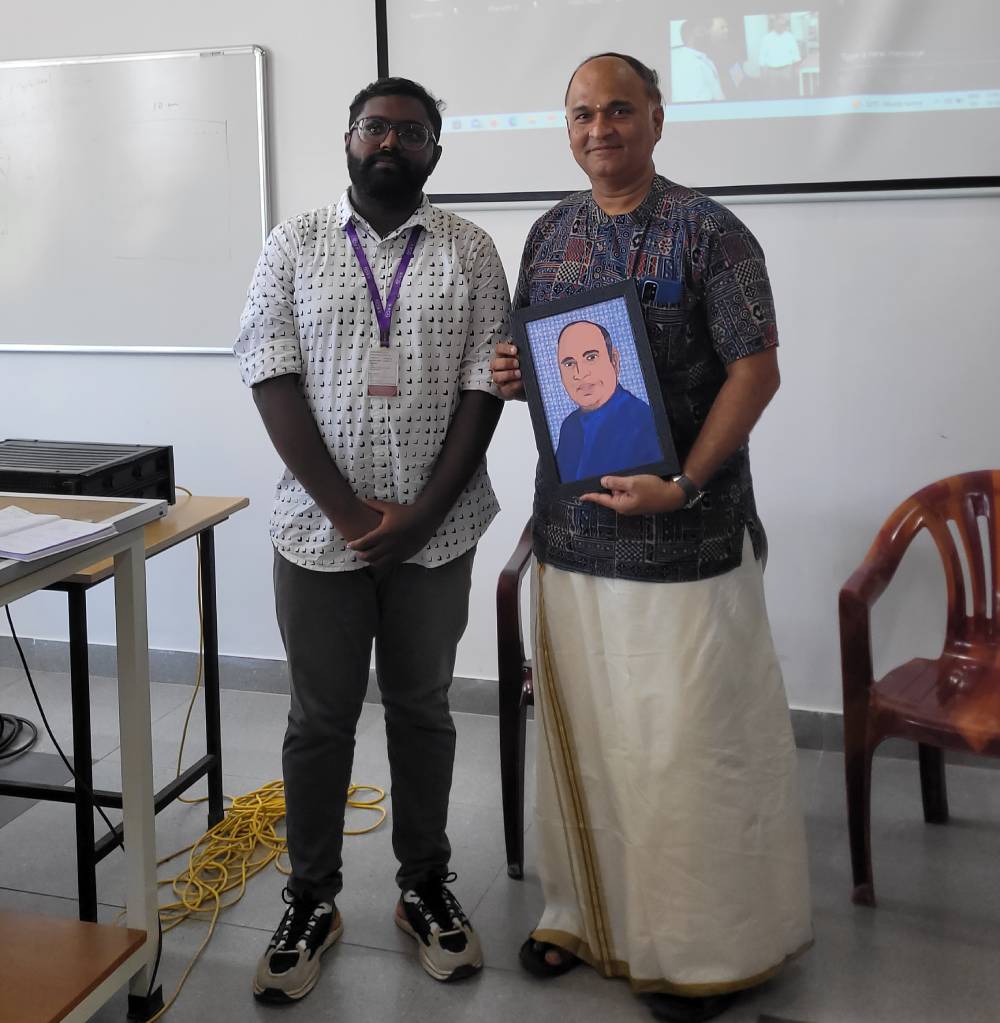

Prepared a memento consisting the guests’ portrait

SEI~GAI a Tamil word meaning “action” or” helping hand”, is a brand inspired by the tireless and selfless service of our COVID Frontline Warriors. It is an initiative of the students of the Fashion Technology Department of KCG College of Technology, Chennai.

Click Here : https://kcgfashiontech.wordpress.com/seigai/

Final year students attended the placement drive organised by M/s. Decathlon Sports India at Anna University on 6th October 2023. After the internal mock interview, 13 students attended the drive along with 25 students from B. Tech. Textile and Apparel Technology students from AU.