About the Department

-

The Department of Mechatronics Engineering in KCG college of Technology is well-known for its cutting-edge, cross-disciplinary background and modules .

-

We have creative laboratory infrastructure and faculty members with a wide range of research interests, as well as productive collaborations with a variety of industry partners, ranging from start-ups to large corporations.

-

The aim of our study is to impart knowledge and skill required to integrate elements of mechanical, electrical, electronics through complex software algorithms for control and overall functioning of the system and to address industry challenges, advance understanding, and aid in the training of highly qualified “Mechatronics Engineers”.

-

Mechatronics research lab equipped with PLC, Microprocessors and Microcontrollers, IoT, Single Arm ROBOT, Delta Model 3D printer, FABX PRO 3D printer, Hydraulic and Pneumatic circuit In aluminum Cast Model and softwares such as MATLAB, Simulink, SOLIDWORKS, ANSYS , Hydro and Pneumo SIM.

-

We’re also excited about the prospect of collaborating with the mechatronics and Robotics industry on the growth of commercial products and applications.

Vision

The department aims to be recognised as a global centre of excellence with interdisciplinary approach for technical education, automation and research catering to the needs of industry and society

Mission

- Impart high quality education in Mechatronics engineering

- Establish state of the art facilities for innovation research and consultancy.

- Mentor the students to develop research and entrepreneurial capabilities and contribute to the needs of industry and society.

- Inculcate an interdisciplinary approach to system design.

Programme Educational Objectives

The Graduates of B.E. (Mechatronics Engineering) will be able to

- Engage in product development and applications in the field of Automation and Mechatronics systems using tools to enhance productivity

- Execute their knowledge of basic engineering sciences in Interdisciplinary systems

- Take active leadership roles with societal and environmental implications accompanied by ethical behaviour and pursue life long learning in emerging technologies.

Program Outcomes

The graduates of B.E (Mechatronics Engineering) will be able to :

| PO 1 | Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems. |

| PO 2 | Identify, formulate, research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences. |

| PO 3 | Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations. |

| PO 4 | Use research based knowledge and methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions. |

| PO 5 | Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modelling to complex engineering activities with an understanding of the limitations. |

| PO 6 | Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice. |

| PO 7 | Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development. |

| PO 8 | Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice. |

| PO 9 | Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings. |

| PO 10 | Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend an write effective reports and design documentation, make effective presentations, and give and receive clear instructions. |

| PO 11 | Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments. |

| PO 12 | Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change. |

Program Specific Outcomes

The graduates of B.E (Mechatronics Engineering) will be able to:

- Apply their knowledge in basic sciences and mechatronic systems for solving complex problems

- Design and program the mechatronic systems for industrial automation with embedded systems, PLC and control systems with MEMS, sensors and actuators

- Engage in life long learning and follow ethics in their profession

| B.E. – Mechatronics Engineering – 4 Years (Affiliated to Anna University) |

Regulation – 2017 | Curriculum and Syllabus | Open Electives |

| Regulation – 2021 Verticals | |||

Electro-Mechanical Engineering

Analyses, designs, manufactures, and maintains equipment and products that are focused on a mixture of electrical/electronic circuits and mechanical systems.

Sensors and Sensing Technology

Sensing technology, is a technology that uses sensors to acquire information by detecting the physical, chemical, or biological property quantities and convert them into readable signals.

PLC Systems

A programmable logic controller, also known as a programmable controller, is an industrial digital computer that has been ruggedized and optimised for the control of manufacturing processes such as assembly lines, robotic systems.

Robotics

Robotics is a multidisciplinary discipline combining computer science and engineering. Robotics is the study of the design, development, function, and application of robots. Robotics aims to create robots that can support and aid humans.

Industrial Engineering

Industrial engineering is a branch of engineering concerned with the growth, improvement, and implementation of integrated systems of people, money, expertise, information, and equipment in order to optimise complex processes, systems, or organisations.

Micro and Nano Engineering

Fabrication, characterization, construction, and simulation of small structures and devices, as well as their incorporation into engineered systems, are all covered by Micro and Nano Engineering.

Computation Based Mechanics

Computational mechanics is the branch of science that studies phenomena controlled by mechanics concepts using computational methods.

Automation

Automation refers to a group of technologies that reduce the need for humans to intervene in processes. Predetermining decision requirements, subprocess relationships, and associated behaviours — and encoding such predeterminations in machines — reduces human involvement.

Course Contents

- Introduction to Robotics

- Spatial Representation of Object

- Transformation, rotation transformationsand DH Parameter.

- Virtual models of Industrial Robots

- Robot Kinematics using Robo Analyzer

- Understanding coordinateframes and transformations

- Workspace analysis ofa 6 axis Robot

- Robotics and Embedded Systems

- Raspberry PI , Arduino and its Applications

- Build your own bot

Introduction to Robotics

Robotics Simulation for Manufacturing

Value Added Program (Robotics and Automation)

Laboratory

Leonhard Euler Strength of Materials Lab

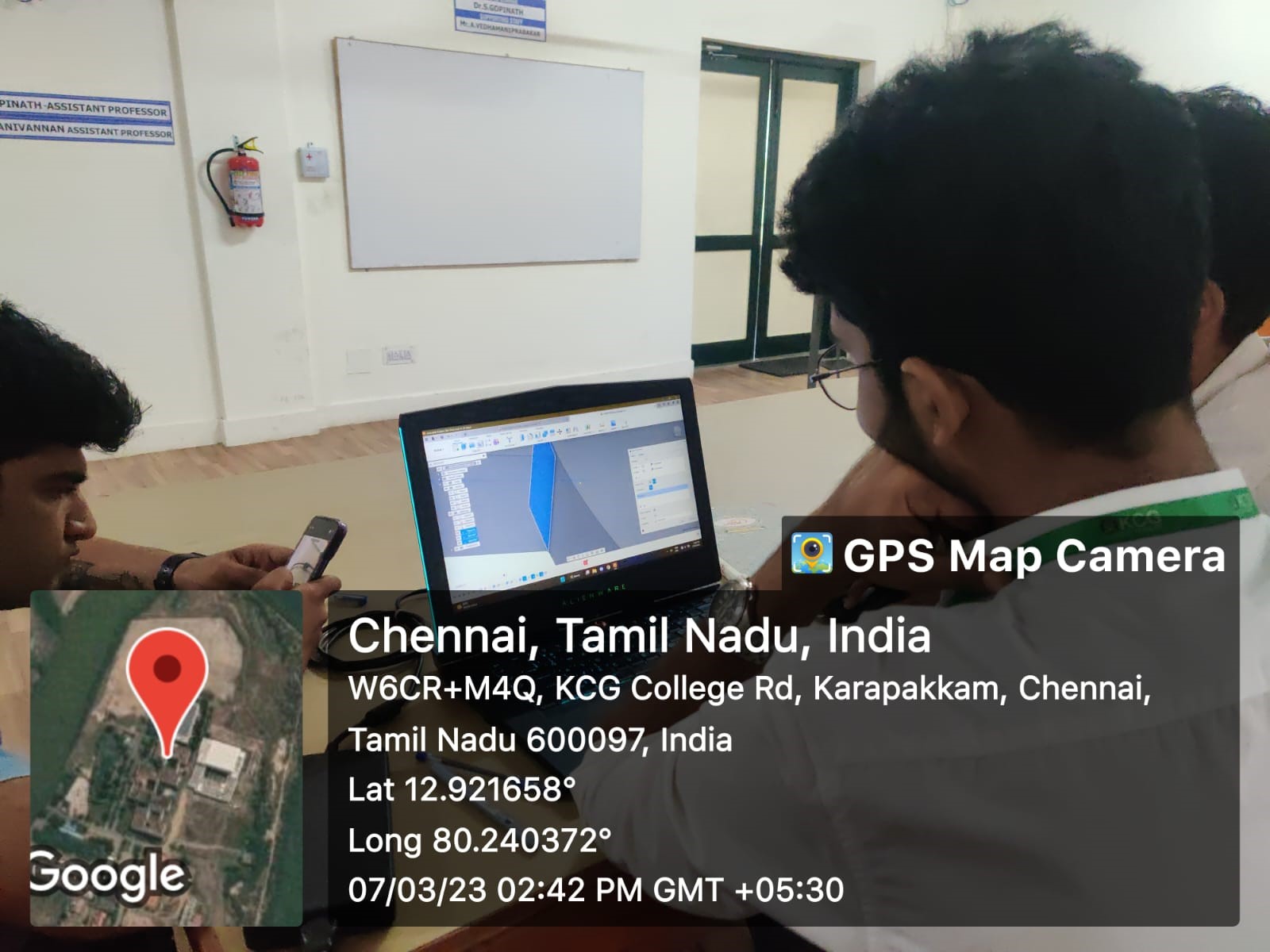

John A. Swanson CAD/CAM Lab

Automation Lab

CAD Lab

Henry Maudslay Machine Shop

Thermal Engineering Lab

CDCE

Automation

Laboratory

Sir Srinivasa Ramanujan – Microprocessor & Microcontroller Laboratory

Linear

Integrated Circuits

Laboratory

Dr.Subrahmanyan Chandrasekhar

Electronics

Laboratory

Dr. Jagdish Chandra Bose

Communication Systems

Laboratory

Charles Babage

Computer

Centre

| Mechatronics and Robotics | AI and Computational | Electrical and Electronics | Management |

| Mechatronic system and Robotics | Artificial intelligence | Renewable systems | Master in International management |

| Medical Robotics | Machine learning | Power Electronics systems | MBA |

| Aerial robotics

|

Data analytics | Digital signal analysis and signal processing | Master in Industrial management |

| Robotics – Yaskawa, Kuka , Irobot, ABB, FANUC India, Epson Robots, DRDO . |

| AI & Machine Learning – IBM, Intel, Microsoft, Apple, Reliance, Tata. |

| Electrical Systems- Schneider, Siemens, Boeing, google ,BHEL, Valeo . |

| Control Engineering L&T, Robert Bosch,GE ABB. |

| Medical Devices & Medical Technology- Medtronic, Johnson &Johnson, Abbot, Poly Medicure. |

| Computation and Image Processing Accenture, IBM ,Google, Amazon. |

| Sensing Technology- Infineon, Maruta, TE, Omaron, NXP Semiconductors, Honeywell. |

| Automation and Industrial Technology – Schneider, Yokogawa, TATA, Honeywell, ABB |

2019-2023 MECHATRONICS BATCH

| S. No | NAME OF THE STUDENT | PLACED COMPANY |

|---|---|---|

| 1. | FADIL P P | GUVI GEEK NETWORK PVT. LTD. |

| 2. | GOKULAKANNAN. R | JBM GROUP- NEEL METAL PRODUCTS LTD. |

| 3. | HARIPRASATH. J | AUTOMOTIVE ROBOTICS [INDIA] PVT. LTD. |

| 4. | HEMANTH. K S | CONCENTRIX TECHNOLOGIES [INDIA] PVT. LTD. |

| 5. | JAGADISH. J S | QUANTIC TECH ANALYSIS PRIVATE LIMITED |

| 6. | NAVEEN P | LUCAS-TVS LIMITED |

| 7. | SANJAY GANESH B | LUCAS-TVS LIMITED |

| 8. | SHYAM K S | AVA SOFTWARE PRIVATE LIMITED |

| 9. | SIVASEKARAN S | LUCAS-TVS LIMITED |

| 10. | SUNDAR R | LUCAS-TVS LIMITED |

| 11. | VISHAAL R | INSPIRE CLEAN ENERGY |

| 12. | DHANUSH. K. R. | KAAR TECHNOLOGIES |

| 13. | GOWTHAM. S | TATA AUTOCOMP SYSTEMS LIMITED |

| 14. | NELSLIN N S | JOY TECHNOLOGIES |

| 15. | VASANTH SOLOMON. S | LUCAS-TVS LIMITED |

| 16. | VIGNESH S R | NOKIA SOLUTIONS & NETWORKS INDIA PVT. LTD. |

| 17. | VIGNESHWARAN. S | JOY TECHNOLOGIES |

| 18. | S. VINOTH KUMAR | NOKIA SOLUTIONS & NETWORKS INDIA PVT. LTD. |

Department organize Seminar/Workshop for students in every academic year with hands on experience to fill the gap in the curriculum through various industry, Government professional etc. In addition, this is a medium which let them know the opportunities in higher education also.

Robotics Workshop Sparkle bot

Robotics Hands-On Workshop

Two day Hands-on Training (Workshop) on FUSION 360 (Autodesk)

Basics of Robotics

Build your own bot

Make an Enquiry for Admission 2024

Come join one of the best private engineering colleges in Chennai.