About The Department

KCG College of Technology has introduced 4 years B. Tech. Fashion Technology program from 2018-19 academic year. The program aims to inculcate technical expertise and a creative edge amongst the students who aspire to become fashion technocrats. The students will be trained to produce innovative, aesthetic and functional fashion products paving way to establish sustainable fashion business.

The Department aims to provide hands on experience on the best practices followed in the global apparel industry. Apart from classroom lectures, the students will be given opportunities to interact with industry experts through lectures, seminars, analytical and problem solving exercises, case studies, courses offered by industry, intensive internships, and real time research projects,. This value added education of the institute drives the students to professionally survive in the international apparel arena too.

Vision

The Department of Fashion Technology aims to be a centre of excellence to create fashion technocrats by inculcating creativity, technical expertise and managerial proficiency for contributing innovative, aesthetic and functional fashion clothing to the society.

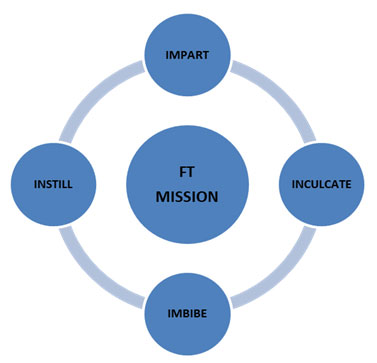

Mission

- Impart comprehensive knowledge and hands on experience of best practices followed in the areas of apparel manufacturing, marketing and management

- Inculcate creativity, analytical thinking and distinctive attitude for providing techno-economic solutions to manage the apparel industry.

- Imbibe professional approach through industry collaboration to face the domestic and international apparel arena.

- Instill entrepreneurial skills with social commitment to become pioneers in contributing essential, ingenious and sustainable fashion products with ethical values.

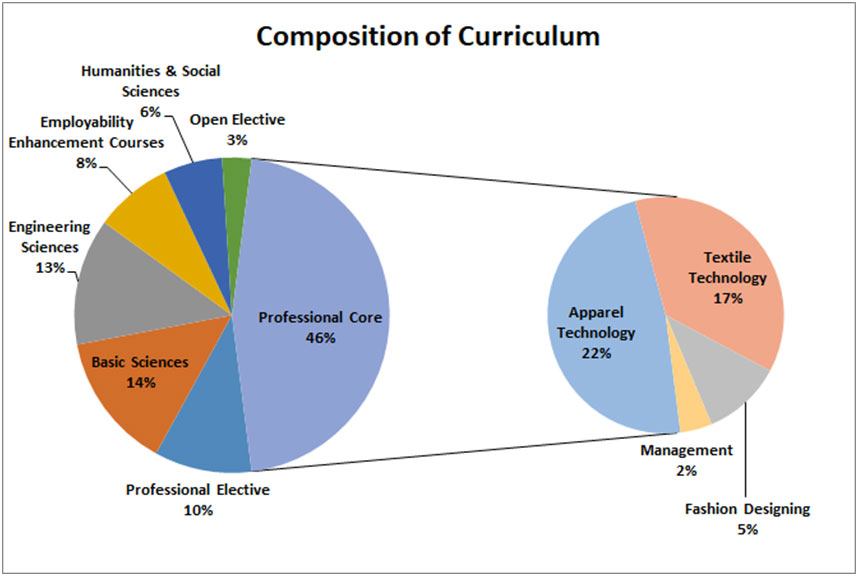

About the Curriculum

The curriculum of the program equips the students to become entrepreneurs or get employment opportunities in various apparel domains like custom tailoring, exclusive hi-fashion and domestic and international corporate brands.

Professional skills acquired

The program covers the broad areas of Textile Manufacturing and Technology, Apparel Manufacturing and Technology, Fashion and Textile Designing, Marketing and Management.

Students will confidently face the competitive edge prevailing in the ubiquitous fashion industry with their acquired flare in:

- Analyzing market and understanding the market demands

- Interpreting fashion/market trends

- Assimilating fashion forecasts and reflecting them in the Apparels

- Conceiving inspirations and market requirements to practical garment/textile designs

- Presenting apparel designs professionally which can efficiently communicate to all strata of the apparel industry

- Using modern engineering tools and software to create digital apparel designs

- Selecting suitable raw materials like fabric, trims and accessories to create comfortable and functional apparels

- Collecting and analysing anthropometric data to achieve perfect garment fit.

- Transforming fabrics from 2D to 3D through pattern making and garment construction techniques

- Selecting right Apparel machineries for better production and productivity

- Adopt the apt marketing and merchandising techniques to reach the right customer

- Utilizing the social media with professional expertise for Apparel E-commerce.

Courses offered

Textile Technology

- Basics of Textile Technology

- Technology of Spinning Processes

- Characteristics of Textile Fibres

- Textile Chemical Processing

- Fabric Manufacturing

- Knit Fabric Production

- Textile Quality Evaluation

- Woven Fabric Structures

- Fabric Analysis Laboratory

- Textile Chemical processing Laboratory

- Textile Quality Evaluation Laboratory

Fashion Designing

- Concepts of Fashion and Design

- Fashion Evolution

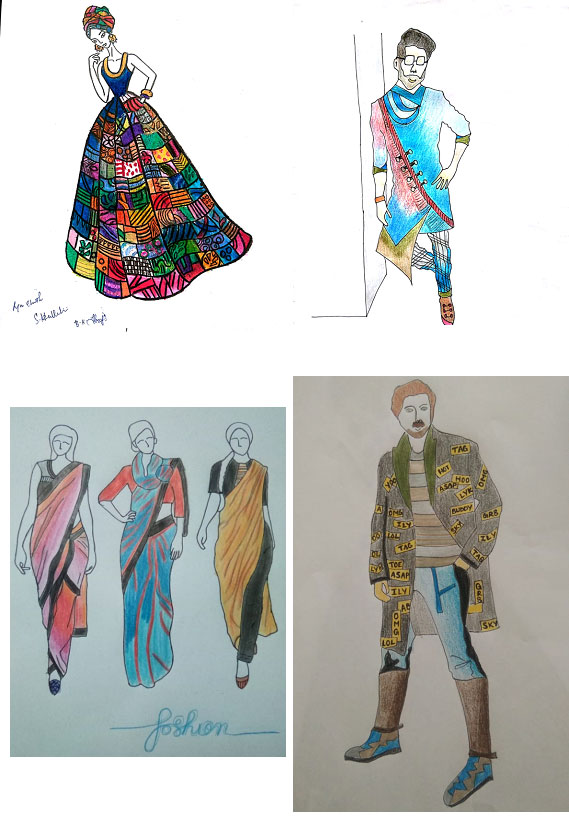

- Fashion Illustration Laboratory

- Fashion Design Laboratory

Apparel Technology

- Fundamentals of Garment Manufacturing

- Pattern Engineering

- Garment Production Machinery

- Garment Construction

- Industrial Engineering in Apparel Industry

- Apparel Production Planning and Process Control

- Apparel Costing

- Garment Finishing and Clothing Care

- Garment Accessories and Embellishments

- Pattern Engineering Laboratory

- Garment Construction Laboratory

- Garment Machinery Laboratory

- Computer Aided Garment Design Laboratory

Professional Elective

- Computer Application in Apparel Industry

- Knit Wear Development

- Denim Manufacturing

- Protective Garments

- Apparel Size and Fit analysis

- Intimate Apparel

- Clothing Comfort

- Production and Application of Sewing Threads

- Home Textiles

Management

- Apparel Marketing and Merchandising

Fashion Photography

- Fashion Portfolio Development

- Application of ERP and MIS in Apparel Industry

- Disaster Management

- Quality Assurance in Fabric and Garment Production

- Fashion Management

- Operations Research in Textile Industry

- Intellectual Property Rights

- Professional Ethics in Engineering

- Retail Management and Visual Merchandising

Co-curricular Activities:

In every Semester

- Two Industrial visits

- One Work shop

- Two Guest Lectures

- Technical Presentations

Final Semester

- Presenting the collections

In every Year

- Technical Symposium

- Short Term Training Programme

In Sixth Semester

- Exhibiting the students’ work

The following laboratories have been planned with the state–of-the -art machineries and equipment to impart skills and hands on experience on the best practices followed in the global apparel industry,.

- Fashion Design Laboratory

- Pattern Engineering Laboratory

- Basic Garment Construction Laboratory

- Advanced Garment Construction Laboratory

- Textile Chemical Processing Laboratory

- Fabric Analysis And Textile Testing Laboratory

- Computer Aided Garment Design Laboratory

All the laboratories of the department are equipped with state-of-the-art machineries and equipment, planned with efficacies required for a production unit to serve dual purposes of training and undertaking production. The infrastructure is upgraded from time to time based upon the inputs from our strong advisory board in order to give hands-on-training to the students to meet the industry expectations. To be abreast with the skill intensive and fast moving fashion industry, all the laboratories are equipped with smart learning aids like over-head projectors, internet connections and video enabled live demonstration of the practical sessions.

Fashion Designing Laboratory:

Fashion designing lab, houses drawing tables and display boards. This lab helps to nurture the creativity and sketching skills inevitable for the fashion technologists. This lab paves way for the students to explore the application and efficacy of various colours, drawing media, substrates and the impact of their combinations. They learn to develop model drawing, attractive and communicative fashion sketches, fabric rendering and informative technical drawings.

Pattern Making Laboratory:

This laboratory is equipped with cork top tables, dummies and mannequins of varied sizes. The students understand the ways of measuring various body measurements of male, female and kids on humans. Dummies help students to acquire affluence in the art of draping and the skill of taking body measurements. The cork top tables help the students to draft basic garment patterns and practice flat pattern techniques to derive new garment designs from basic garment styles. An exclusive retail window also has been set up for students to display garments styles produced by them and also showcase the creative skills of visual merchandising.

Basic and Advanced Garment Construction Laboratory:

The garment construction labs have been furnished with state-of-the-art infrastructure to accomplish the requirements of a stand-alone garment unit and can cater to the production requirements as well as students’ training. The sewing machineries in the labs are Single needle lock stitch machines, flatlock machines, overlock machines, button stitching & holing machines, feed-off-the-arm machines, embroidery machines, computer-controlled sewing machines and fabric cutting machines. The students will be given intensive hands-on-training in operating and troubleshooting of all the machines. They will be given intense training in performing various garment construction techniques in the sewing machines as per quality and techno-economics expected by the industry.

Textile Chemical processing Laboratory:

Colors, patterns and various types of value addition are very significant Unique selling propositions (USP) of garments, which have the ability to influence mood, reflect the wearer’s personality and make them presentable and comfortable. The laboratory is equipped with facilities for sample dyeing, finishing, printing and fastness testing. The students will be trained in preparatory processes, dyeing and printing in different styles and methods on various textile raw materials. Some of the major equipment are Vats, pilot padding mangle, HTHP beaker dyeing machine, pilot curing chamber, spectrophotometer, laboratory drum machine etc.

Fabric analysis and textile quality evaluation Laboratory:

Garment manufacturing involves several raw materials and many production processes, and the quality of each of them contributes to the final performance of the garment. To achieve expected performance of the garment, the specification of the raw materials and parameters of the processes have to be stringently maintained through various testing methods. The laboratory is well equipped to hone the students in the testing and analysis of fibre, yarn, fabric, garments and trims as per various standards followed in the textile and garment industry. Beesley’s balance, fibre fineness tester, twist tester, yarn/fabric/seam strength tester, yarn evenness tester and various fabric testing equipment like tearing, thickness, stiffness, crease recovery bursting, abrasion, pilling, air permeability are some of the major equipment in the laboratory.

Computer Aided Garment Designing Laboratory:

This lab facilitates the students to improve their skills in using the modern tools for designing garments, woven, knitted and embroidered fabrics & pattern making, grading and marker planning. This lab has computers, digitizer, plotter, scanner and software for fabric designing, fashion designing, and garment designing. This lab will help the students to develop the soft skills required in developing E-prototypes with the speed and quality expected by today’s fast fashion industry. The skills acquired in this lab gives a great amount of confidence to the students as they can get multiple diversities and can sought careers in various coveted fashion fields.

|

|

|

| Proposed Fashion Design Laboratory | Proposed Pattern Engineering Laboratory | |

|

||

| Proposed Garment Construction Laboratory | ||

Eminent Industrialists and Academicians of the Apparel domain constitute the Department Advisory Board for planning value added programmes to bridge the gap between curriculum and the requirements of the diversified Apparel Industry.

| Dr. S. Subramanian | Associate Professor & HOD i/c, Department of Textile Technology, Anna University, Chennai |

| Dr. Afrose Fathima F | Professor and HOD, School of Fashion Design, Hindustan University, Chennai |

| Mr. Ravi Singhee | Managing Director M/s. Magnum Clothing Pvt. Ltd., Chennai |

| Mr. N.K. Srinivasan | Production Technologist (Quality) Tesco Sourcing India Pvt Ltd., Bengaluru |

| Mr. K.S. Yuvaraj | Manager – Merchandising Tres Mercari Pvt. Ltd., Chennai |

| Mr. Lakshimi Narayana P | Assistant Director MSME Development Institute, Chennai |

| Mr. Somasundaram. G | South Zone Head, Skill Development (Textiles & Clothing) IL &FS, Bengaluru |

| Mr. Kotteswara Rao | F/o. K. Thanuja, 1st year B.Tech. FT, Needle Stitch India Limited, Chennai |

|

First meeting of Department Advisory Board |

|

| Academic Career | Entrepreneurs | Employment | Employment |

|

|

|

|

Admissions: Eligibility Criteria

- (10+2)/ HSC (Academic) or Equivalent,

- HSC (Vocational)

- PRELIMINARY REGISTRATION for admission to a course can be made ONLINE. Click https://admissions.kcgcollege.ac.in/ to go to Admissions 2019 page to make your registration.

- Application for admission to a course under Management Quota may be made through consortium of self-financing Arts & Professional Colleges in the prescribed form, which will be sent along with the prospectus.

- For Admission under Government Quota, Government norms and guidelines have to be followed.

Admission to direct second year program- Lateral entry scheme:

Diploma Candidates:

A pass with minimum eligibility marks in one of the Diploma Courses in Engineering / Technology of the State Board of Technical Education and Training, Tamil Nadu / Equivalent prescribed for the respective Degree Courses. Viz. Diploma in – Textile Technology, Garment Technology, Textile Processing, Designing & Weaving, Handloom & Textile Technology, Khadi & Handloom Technology, Manmade Fibre Technology

B.Sc. Candidates:

A pass with minimum eligibility marks in any recognized Bachelor’s Degree in Science with minimum 3-years duration with (10+2+3) pattern of study with Mathematics as one of the subjects at the Degree level.

Make an Enquiry for Admission 2020

Come join one of the best private engineering colleges in Chennai.